[ad_1]

Electric vehicles (EVs): sharing a common language for a sustainable future

The climate crisis is becoming increasingly pressing, and demand for electric vehicles (EVs) is booming. Engineering these EVs calls for new ways of working: as we move towards the electric future, battery and body in white (BIW) teams will need to work together for the first time.

This whitepaper reviews the unique challenges that come with the EV engineering process throughout its major stages, introducing the engineering requirements of integrating a battery pack into vehicle design. It then presents the solution: to implement a common engineering software platform to allow different teams to work seamlessly together. Manufacturers which embrace this opportunity will thrive in the electric future.

by Siemens

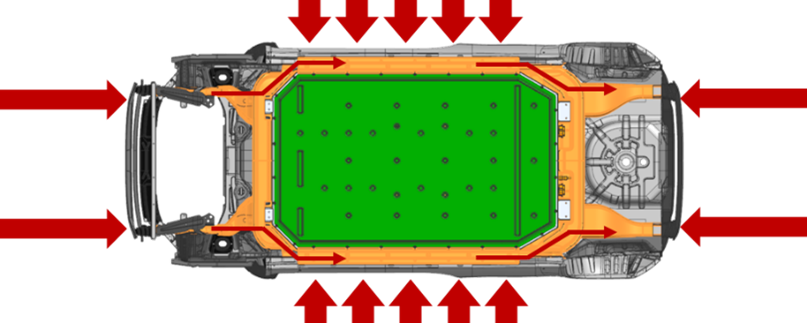

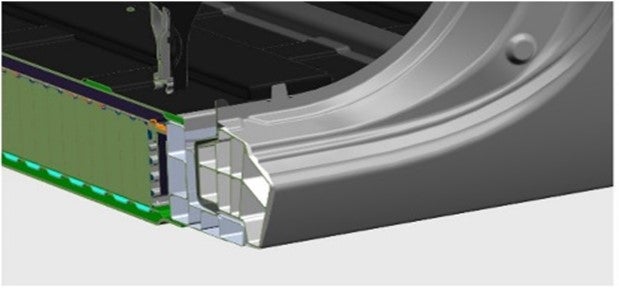

One of the most significant differences of an EV BIW, relative to an internal combustion engine (ICE) vehicle BIW, is the need to maintain both occupant and battery safety by avoiding pack intrusion in a crash. This is accomplished in part by transferring crash loads around the pack for frontal and rear collisions. One of the greatest design challenges is to make sure that the battery pack is protected in the event of a side impact crash or collision. This is especially challenging since there is limited space in a rocker or sill for the crumple zones needed to absorb side impact crash loads without damaging the batteries.

Many OEMs have somewhat standardized EV vehicle platforms on which they build their different models. A particular battery pack structure may be common to many models with different upper body shapes such as a sedan, hatchbacks or SUV. As the model’s number or diversity increases, combined with a lack of experience of designing bodies for electric vehicles, new design challenges are posed for EV BIW engineering teams which may have to satisfy design constraint across several vehicle models.

Compensating for overall weight reduction

Lightweighting is also important especially when reaching target range is in question and the solution is to add more batteries and consequently more weight. Here is where innovative use of materials can help reduce overall battery pack weight.

Over the past few years, as new forms of steel have become more weight and cost efficient, there has been a resurgence in the use of steel to replace aluminum and composites to reduce BIW weight. However, for battery pack structures, aluminum is typically employed in all but the lowest price market segments. Even composites are utilized in design of pack covers especially when complex cover shapes are required.

Battery pack integration optimization

In order to optimize the pack to body integration, it is critical to consider the impact of electric and mechanical features to ensure vehicle specifications are satisfied. This includes assessment of numerous design parameters on vehicle range, comfort and cost. For instance, features that are typically evaluated include the location and number of structural cross members, fastener type and location or the use of adhesives. As more batteries are added to achieve range alternatives in battery module location must also be evaluated as to how module placement impacts packaging or performance. And of course, passenger comfort from an acoustic, vibrational and thermal aspect is always a consideration as is cost and manufacturability.

Since engineering of the BIW for ICE vehicles is well understood based on many years of experience, developing best practices, current engineering solutions are not always well suited for unique EV design challenges such as pack to BIW integration. Due to the number of features being considered, possibly for the first time on a new EV vehicle program, engineering solutions that can quickly evaluate numerous design feature sets to find optimal combinations can be useful to virtually assess design alternatives before final implementation.

Such solutions can help ensure efficient integration of the battery pack within the BIW provide for the efficient evaluation of electrical and mechanical design features.

Electric vehicles (EVs): sharing a common language for a sustainable future

The climate crisis is becoming increasingly pressing, and demand for electric vehicles (EVs) is booming. Engineering these EVs calls for new ways of working: as we move towards the electric future, battery and body in white (BIW) teams will need to work together for the first time.

This whitepaper reviews the unique challenges that come with the EV engineering process throughout its major stages, introducing the engineering requirements of integrating a battery pack into vehicle design. It then presents the solution: to implement a common engineering software platform to allow different teams to work seamlessly together. Manufacturers which embrace this opportunity will thrive in the electric future.

by Siemens

[ad_2]

Source link